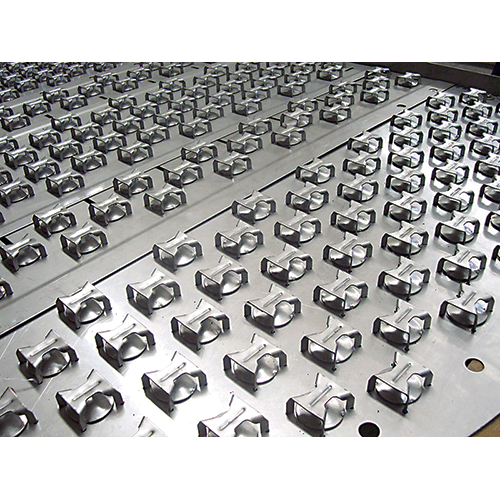

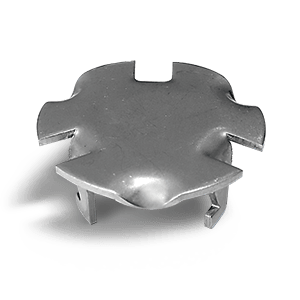

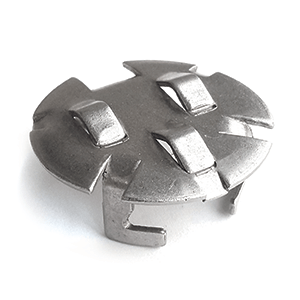

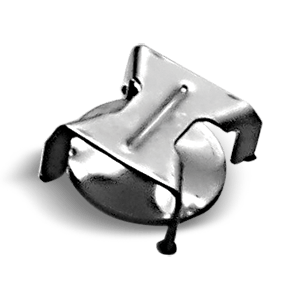

Float Valve Trays are composed of punched tray decks fitted with movable valves to vary the tray open area with changing vapor load. In cases where high turndown ratios are considered, floating valve trays are an option. There are various valve types which may either have legs integrated to the valve disc to limit upwards movement or alternatively the valve disc movement is restricted by a cage fitted to the tray panel.Valve discs/caps are available in both round and rectangular shapes. The capability of floating valves makes these valves to control vapor flow so as a result, they provide better sustained efficiency over a wider operating range than sieve trays.

Features

- Medium operating flexibility up to 5:1 turndown ratio

- Enhanced liquid-vapor contact

- Steady liquid movement across the tray deck

- Less froth height and weeping

- Turndown parameters adjustment by selecting suitable range of valve lift and weight

- More resistance against fouling or corrosive fluids

- Extra fatigue causes the legs to be damaged; cage valves solve this problem easily