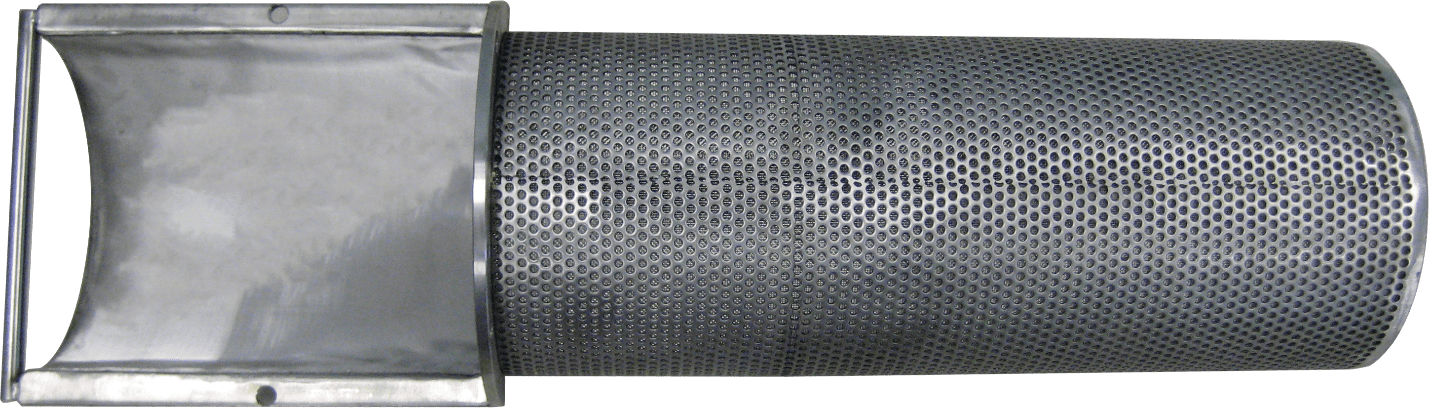

Strainers are known as pipe fittings whose main function is to protect downstream devices or process from impact of impurities that may block narrow passageways, abrade sensitive surfaces or taint the product. They are simple coarse filters using perforated plates, wire mesh or wedge wire (called straining elements) as the filter medium which remove solid material including dirt, dwarf, weld sputter, scale, nails and screws, organic material and so on. After a while, the strainer becomes clogged with debris. The straining element which holds these unwanted materials, should be periodically removed, cleaned and put back inside the pipeline to maintain an uninterrupted clean flow.

Although strainers are categorized as a type of filters, their primary difference from filters is the size of particulates they are designed to remove. Strainers are commonly used to remove particles in range of 25 mm to 40 microns. For smaller particles usually other types of filters with more complicated filter media are used.

There are different types of strainers depending on the purpose of treatment. Two main categories are temporary and permanent strainers. There are various configurations for permanent strainers as below:

- Y-type Strainers

- Basket Strainers

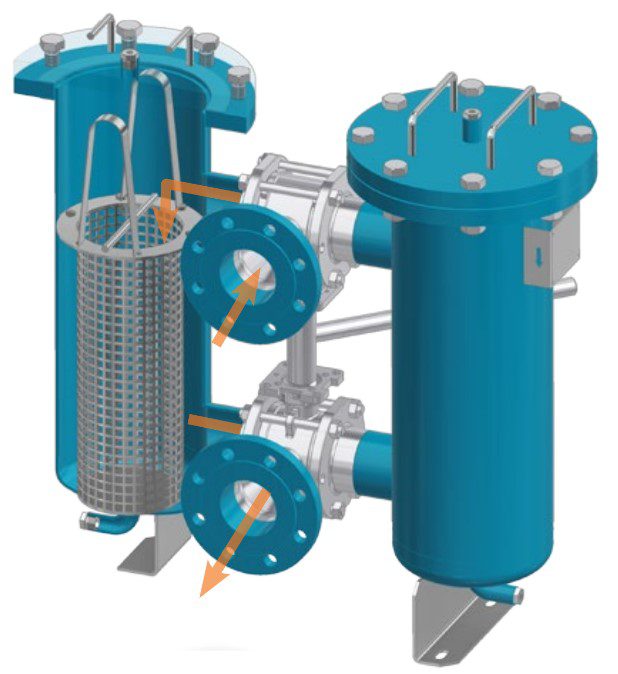

- Duplex Strainers

- T-Type Strainers

Due to nature of their function, strainers are seen in numerous applications such as oil and gas, water treatment, food industry, pharmaceuticals and cosmetics, pulp and paper, paint and ink production, marine industry, power generation, commercial buildings.