Water injection is a common technique used in the oil industry to enhance oil recovery from reservoirs. When oil is initially extracted from a reservoir, it only recovers a portion of the present oil. The remaining oil is trapped in the pores of the rock, and may be difficult to extract.

Water injection systems work by injecting water into the reservoir through injection wells. The water is typically sourced from nearby sources such as rivers or aquifers, and is treated to remove impurities before injection. The water is then pumped into the injection wells at high pressures, which creates fractures in the rock and allows the water to penetrate deeper into the reservoir. This water displaces the oil, pushing it towards the production wells where it can be extracted.

To treat water before injection into an oil reservoir, the following steps are typically taken:

- Screening

- Filtration

- Disinfection

- Dechlorination

- pH adjustment

- Scaling control

- Corrosion inhibition

- Dearetion

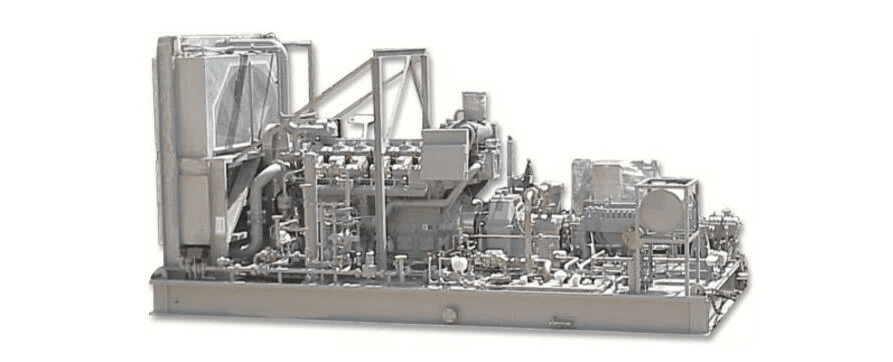

PANTAN offers personalized water injection packages that include water treatment and pumping equipment and control system for both onshore and offshore applications.