When it comes to fractionation towers, the choice of trays is crucial for achieving efficient mass transfer processes. PANTAN takes pride in designing and manufacturing a diverse range of fractionation trays that applicable to various industry needs. With different types of tray openings and downcomers, PANTAN offers customized options to meet specific client requirements.

- Float Valve Trays are composed of punched tray decks fitted with movable valves to vary the tray open area with changing vapor load. In cases where high turndown ratios are considered, floating valve trays are an option. There are various valve types which may either have legs integrated to the […]

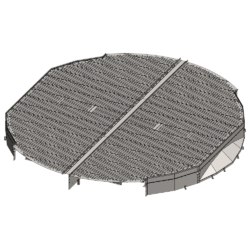

- Consist of tray panels area uniformly punched with 13 mm holes and approximately 10% open area which use because of their simplicity, versatility, capacity and cost effectiveness Features Simple and low cost Narrow operation flexibility over a range of 2:1 turndown ratio Tried and tested performance

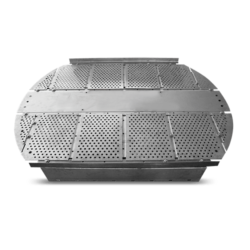

- Cartridge trays are typically used in flanged columns where the tower diameter is so low and no manhole is used. Generally, for columns with diameters less than 900 mm any of tray products can be manufactured in cartridge-style construction. This scheme can only provide up to 5 trays per cartridge […]

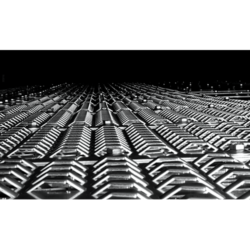

- In order to provide higher capacity and to reduce Jet Flood, PANTAN offer complete range of high performance trays based on optimum tray geometry design, such as high performance chordal downcomers, Swept-back Downcomers, Sloped Downcomers and Multi-downcomer trays, Special tray decks for enhancing vapor capacity with state-of-the-art downcomer technology. These […]

- This type of valve tray has been developed to achieve both sieve and floating valve tray specifications as moderate pressure drop, turndown ratio and cost. Fixed Valve Tray is the preferred tray when fouling conditions are possible. However, it provides lower turndown and less efficiency than floating valve. Smaller fixed […]