To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed.Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications:

Uniform liquid distribution

Operation flexibility through the turn down range

Low vapor pressure drop

Low liquid residence time

Capability to be used as combined with collector for re-distribution

Minimum distributor height

Fouling resistance

Cross mixing capability

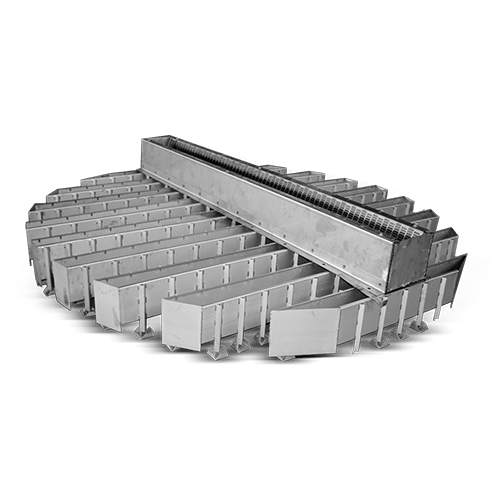

Properties Table of Distributor Model TD-111

| Type | Drip Tube Trough Distributor |

| Diameter | >1000 mm |

| Irrigation Rate | 0.8 – 30 m³/hm² |

| Resistance to Fouling | High |

| Turndown Ratio | 2:1 (maximum 10:1 in multiple level holes) |

| Holes Position | Square pattern punched in the trough’s side which is covered with drip tubes (Multiple levels & series of holes can be punched to achieve high turndown ratio) |

| Drip points Density | 80 – 100 drip points/m² |

- Liquid Collector/Chimney tray is used in the columns to achieve one or more of following purposes: Vapor distribution Liquid collection from above bed and conduction to below distributor Total or partial liquid draw-off Open area, allowable pressure drop, height of collector liquid & vapor loads, column diameter and quantity of […]

- Cartridge trays are typically used in flanged columns where the tower diameter is so low and no manhole is used. Generally, for columns with diameters less than 900 mm any of tray products can be manufactured in cartridge-style construction. This scheme can only provide up to 5 trays per cartridge […]

- This Third Generation of random packings is well known as FlexiMax with higher performance, efficiency, and Capacity provide lower pressure drop compared to conventional random packings.besides, this type can tolerate more pressure under deep beds without mechanical deformation. This 3rd generation of random packing media designed to give enhanced capacity […]

- This second generation of random packings is well known as Pall Ring which is one of the most common type of packings media. Features Most experienced random packing in industries and research institutes Improved strength by proper material thickness Lower pressure drop rather than Raschig Rings Nominal Size (mm) Equivalent […]

- Metal Ring RR-PantaRing™ has cylindrical design and is the first generation of random packings, well known as Raschig Ring. Nominal Size(mm) Equivalent Size(inch) Bulk Density(kg/m³) Quantity(Pieces/ m³) Surface area(m²/m³) #25 1” 400 50000 220 #40 1 ½” 245 14500 130 #50 2” 320 6500 110 Carbon Ring Carbon Rings as […]