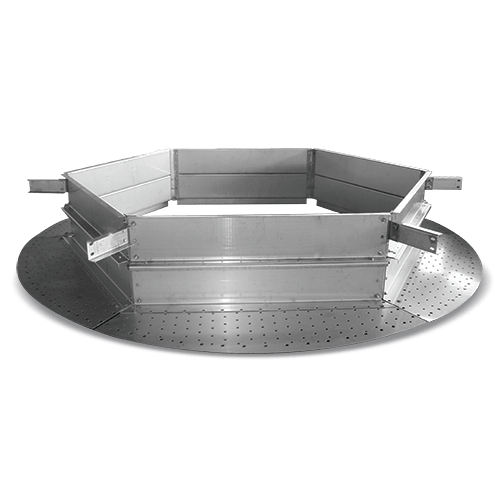

Flashing feed gallery is a feed device to accommodate mixed liquid/vapor or flashing feeds. The 2 phase liquid is fed to the column through a nozzle tangentially against the tower wall. The residence time allowing the vapor phase to disengage from the liquid and the clear liquid then flows directly to a distributor.

- Packings are installed on support grids which are designed to provide sufficient strength to support packed beds under normal operating conditions without creating any capacity restriction in the column. Criteria for selecting a support grid include: Type of packing (random or structured) Maximum design load Properties Table of Support Grid […]

- Packings are installed on support grids which are designed to provide sufficient strength to support packed beds under normal operating conditions without creating any capacity restriction in the column. Criteria for selecting a support grid include: Type of packing (random or structured) Maximum design load Properties Table of Support Grid […]

- An industry standard sheet metal which is available with specific surface ranging from below 125 m²/m³ for high capacity to more than 750 m²/m³ for high efficiency applications. The standard angle of the corrugations which is 45°[referred M1] and 60°[referred M2] also high capacity structured packing [referred MH] are fabricated […]

- This type of Structured Packing is made of mesh type gauze woven by metal wire and is mainly used to enhanced separation characteristics for fine chemicals, perfumery, and pharmacy. It is normally manufactured with very high surface area [500 m²/m³ and 750 m²/m³] Features Superior wetting ability owing to capillarity […]

- Consist of tray panels area uniformly punched with 13 mm holes and approximately 10% open area which use because of their simplicity, versatility, capacity and cost effectiveness Features Simple and low cost Narrow operation flexibility over a range of 2:1 turndown ratio Tried and tested performance

- Liquid only feed pipe is used when liquid is fed from outside the column for distributors. The incoming flow must contain less than 1% vapor by volume. A perforated pipe composed by a main header and secondary flanged branches is typically used for liquid inlets.

- To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed.Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications: Uniform liquid distribution Operation flexibility through the turn down range Low vapor pressure drop Low liquid residence time […]

- To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed.Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications: Uniform liquid distribution Operation flexibility through the turn down range Low vapor pressure drop Low liquid residence time […]

- To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed.Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications: Uniform liquid distribution Operation flexibility through the turn down range Low vapor pressure drop Low liquid residence time […]

- To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed. Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications: Uniform liquid distribution Operation flexibility through the turn down range Low vapor pressure drop Low liquid residence […]

- To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed.Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications: Uniform liquid distribution Operation flexibility through the turn down range Low vapor pressure drop Low liquid residence time […]

- To acquire the maximum efficiency in packed column, liquid should be distributed uniformly over the packed bed.Therefore, Liquid Distributors are used above each bed of packing.Good practice designed distributors have following specifications: Uniform liquid distribution Operation flexibility through the turn down range Low vapor pressure drop Low liquid residence time […]

- Hold Down Grid / Bed Limiter for random packing is used because vapor load has potential for moving the packing media. When top packing layers top have potential of upward displacement in the structured packing, Hold Down Grid is recommended. Where the upward displacement of structured packing is not a […]

- Hold Down Grid / Bed Limiter for random packing is used because vapor load has potential for moving the packing media. When top packing layers top have potential of upward displacement in the structured packing, Hold Down Grid is recommended. Where the upward displacement of structured packing is not a […]

- In order to provide higher capacity and to reduce Jet Flood, PANTAN offer complete range of high performance trays based on optimum tray geometry design, such as high performance chordal downcomers, Swept-back Downcomers, Sloped Downcomers and Multi-downcomer trays, Special tray decks for enhancing vapor capacity with state-of-the-art downcomer technology. These […]

- Float Valve Trays are composed of punched tray decks fitted with movable valves to vary the tray open area with changing vapor load. In cases where high turndown ratios are considered, floating valve trays are an option. There are various valve types which may either have legs integrated to the […]

- Flashing feed gallery is a feed device to accommodate mixed liquid/vapor or flashing feeds. The 2 phase liquid is fed to the column through a nozzle tangentially against the tower wall. The residence time allowing the vapor phase to disengage from the liquid and the clear liquid then flows directly to a distributor.

- This type of valve tray has been developed to achieve both sieve and floating valve tray specifications as moderate pressure drop, turndown ratio and cost. Fixed Valve Tray is the preferred tray when fouling conditions are possible. However, it provides lower turndown and less efficiency than floating valve. Smaller fixed […]

- Liquid Collector/Chimney tray is used in the columns to achieve one or more of following purposes: Vapor distribution Liquid collection from above bed and conduction to below distributor Total or partial liquid draw-off Open area, allowable pressure drop, height of collector liquid & vapor loads, column diameter and quantity of […]

- Liquid Collector/Chimney tray is used in the columns to achieve one or more of following purposes: Vapor distribution Liquid collection from above bed and conduction to below distributor Total or partial liquid draw-off Open area, allowable pressure drop, height of collector liquid & vapor loads, column diameter and quantity of […]